Get Free Trial Week Developer Access, Try Before You Hire. Click Here to Claim Now

Filter By:

Mental Health and Wellness App Development

The client wanted to extend their wellness brand into digital mental health support, so we developed an app that helps users take care of their mind and emotions. Features include mood logging, guided exercises, journaling, personalized recommendations, and secure therapist access. Users can track emotions, build healthy habits, and get professional help whenever needed. Overall, this mental health app increased business upto good extent due to its personalized service and subscription plans.

AI-Powered Matrimonial App Development

This AI-powered matrimonial app allows you to find compatible life partners quickly and securely. We added AI matchmaking, profile verification, preference-based search, live chat, video calls, GPS integration as well as subscription plans and payment options. They can set up profiles, save favorites, and set notifications. The app is secure, trustworthy, and easy to use. This resulted in higher engagement, faster match connections, and greater subscription conversions for the client in the U.S. market.

Weather Forecast App Development

We developed a weather forecast app to solve the problem of unpredictable climate patterns. It provides accurate, farm-level weather forecasts instead of general city data. The app gives early alerts for rain, frost, heat, drought, and storms, along with crop-specific insights. Farmers use these weather app to check insights and manage harvests and optimize water usage to get the most out of their farming. With features like real-time radar and automated safety alerts, the app helps as a critical decision-making tool and reduces crop losses, saves water, and improves overall yield.

AI Meme Creator/Generator App Development

We developed this AI meme creator app to help our UK client in faster memes creation and handle multiple social media needs. Users can generate captions and images using AI, choose trending templates, and maintain consistent brand styles. It allows instant sharing on social media and supports multiple clients at once. Overall, this memes generator app has a smooth, beginner-friendly interface that allows anyone to create memes or posts without having design skills. It helped the client’s business to get the leads and engagement it needed and improved overall campaign stability and budget.

AI-powered Life Coaching App Development

This AI-powered life coaching app helps employees handle everyday challenges, whether it’s setting goals, building habits, or making better decisions. It works like a digital coach, and offers personalized advice, daily motivation, chat or voice guidance, and easy progress tracking with the use of AI. This life coach app provides more realistic conversations due to its core functionality features sentiment analysis and human-like text generation. Overall, it helped the client to enhance workplace performance and cut down traditional learning costs.

AI-Powered Attendance Tracker App Development

Today, attendance tracking has become essential for every company, especially those who work hybrid, remote, and field teams. We developed an AI-powered attendance tracker app for our USA client to help them with record check-ins using face recognition, QR codes, and GPS tagging. We built this automated attendance tracking app with Flutter, on-device AI, offline support, and easy HR/payroll integration. Now, managers can manage in-house and remote employees' attendance from a single app, and it has also improved HR and payroll problems by reducing manual correction work and giving real-time visibility.

Phone Location Tracking App Development

This phone location tracking app was built to help e-commerce logistics clients in the USA to track delivery agents in real time. It solves the problem of delayed or missed deliveries and saves fuel by offering live tracking, route optimization, and instant notifications. With privacy controls, geo-fencing, and performance dashboards, it offers transparency and efficiency. Overall, this app gave complete control to logistics and other vendors to have a transparent and disciplined delivery on time with proper coordination.

Smart Security Camera App Development

We developed a security camera app for a home security agency to help users monitor their homes and loved ones from anywhere. The app offers live video streaming, motion and noise alerts, two-way audio, and multi-camera support, and is easy to keep track of kids, pets, offices, and other places. Users can also take action from the app, like talking from a mic in real-time with the concerned person in a video call. Overall, it provides real-time security and peace of mind to make sure users never lose connection, no matter where they are.

Online Poker Game App Development

Poker is today one of the trending games among youngsters. Our client, a USA startup gaming company, wanted to create a poker app to engage both casual and professional players. We designed and developed a cross-platform app with smooth real-time gameplay, anti-cheating systems, secure payments, and engaging features like tournaments, leaderboards, and chat.

As a result, the client gained high user engagement, steady revenue through in-app purchases, and strong market presence in the competitive gaming industry.

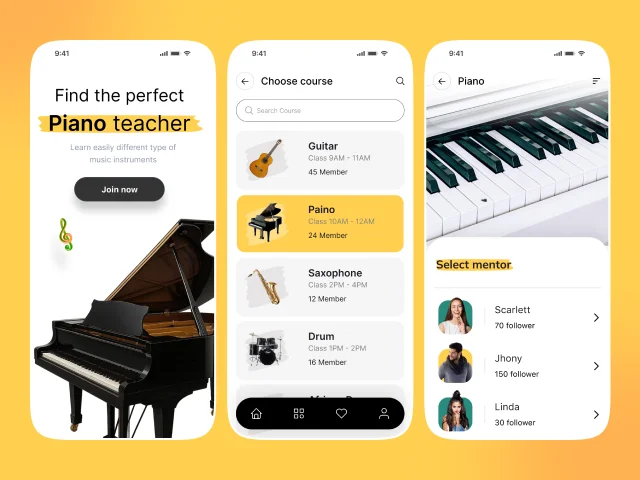

Piano Learning App Development

We built a Piano Learning App for a local music academy to help them provide a personalized piano teaching experience to remote learners. The app includes interactive lessons, real-time feedback, and gamified learning to make piano practice fun and effective. We also added AI to track progress and instructor videos, and smart notifications to develop a daily learning habit to users.

Over time, this piano learning app helped the academy reach more students, boost engagement, and modernize their teaching approach without losing the personal touch of traditional classes.